Vehicle Routing Problem

Common VRP Issues

Source: Vehicle routing problem - Wikipedia

1. Basic VRP

Addresses the optimization of delivery routes with the goal of minimizing costs, travel distance, and time.

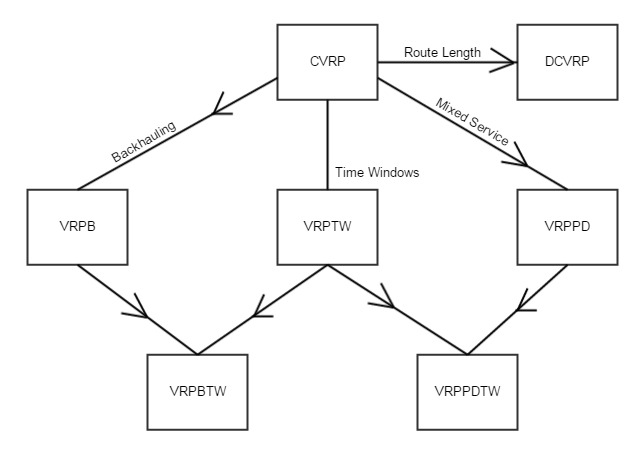

2. CVRP - Capacitated Vehicle Routing Problem

Solves the routing problem with specified constraints.

3. Selective Depot VRP

Addresses routing problems applicable to multi-depot models.

4. VRPTW VRP with Time Windows

Solves routing problems applying specific delivery time windows.

Onwheel's Optimizing Algorithms

VRP

1. VRP

Optimizes the arrangement of picking up from one point and delivering to multiple points. VRP optimizes based on distance, volume, vehicle capacity (if any), etc., to minimize costs and shorten delivery distances.

2. VRP N-1

Optimizes picking up and delivering at multiple points but all converging at one point. Similar optimization conditions to VRP, VRP N-1 optimizes the route for trips with multiple pickup points and only one delivery point.

3. PDVRP

Handles picking up and delivering at multiple points. PDVRP optimizes routes with multiple pickup and delivery points based on VRP's optimization conditions.

4. TWVRP

Optimizes based on time windows (Time-windows VRP). With varying delivery time frames, the RO tool helps classify time frames and arrange routes for orders according to the pre-scheduled time frames.

BY GROUP

1. BY GROUP

Groups points with the same category. The algorithm relies on data that customers have divided for each delivery point and groups delivery points with the same common point into one route.

2. TSP BY GROUP

Groups points with the same category and optimizes the route. Based on the logic of grouping orders with the same category from the BY GROUP algorithm, TSP BY GROUP optimizes the route further after the grouped delivery points form a route.

Common Optimization Mechanisms

Maximum Capacity VRP

Optimizes routes with conditions of maximum size and weight for each order. Orders are routed to meet the maximum size and quantity conditions.

Optimizing with Multiple Pickup Points (Multi-depot VRP - SDVRP)

When there are multiple orders that need to be picked up from various locations, RO helps customers route deliveries by combining pickup points optimally.

Optimizing with Maximum Distance Constraint (Max distance VRP)

Customers can specify a maximum distance for each order depending on the nature of the goods. RO routes orders within the allowed distance, optimizing delivery.

Optimizing with Multiple Combined Constraints (Multi-constraint VRP)

A real-world order often has various constraints (COD, weight, volume, etc.). RO combines orders that meet the customer's given constraints to optimally route the orders.

Optimizing High Volume of Stops

For large customers, when there is a large volume of orders to be delivered to various locations, RO routes instead of humans to arrange the optimal route for the orders.